PROFESSIONAL ULTRASONIC CLEANING SYSTEMS for METAL FILTERS for EXTRACTOR HOODS

MODULAR ULTRASONIC CLEANING SYSTEMS

FASAR UsKIT

Our modular ultrasonic cleaning systems for industry and professional laboratories, combined with appropriate detergents, ensure perfect cleaning of immersed parts, removing any residual dirt. An optimal combination of ultrasonic generator parameters (power, frequency, and modulation), treatment time, and temperature deliver results otherwise impossible with traditional cleaning systems.

Adequately powerful ultrasonic cavitation propagating within a fluid is the only way to meet the most demanding cleaning requirements for metal filters, complex objects impossible to clean with traditional means. Ultrasonic power is generated by a group of piezoelectric transducers that, powered by electrical energy at the appropriate power and frequency, convert it into mechanical vibrational energy. This generates millions of microscopic vacuum bubbles that implode under the pressure variations generated by the ultrasound, removing the most stubborn dirt and grease particles.

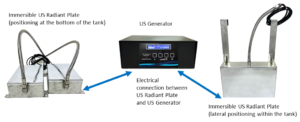

FASAR UsKIT uses a group of submersible AISI 316 stainless steel radiant plates, each powered by its own generator, strategically positioned inside the washing tanks.

The tanks can be made of any material and are already available, chosen based on the size and quantity of filters to be treated.

In a system with submersible radiant plates and independent US generators, the radiant plates are separate modules containing multiple piezoelectric transducers electrically connected in parallel, hermetically enclosed within a rectangular AISI 316 stainless steel enclosure. Each plate connects to an external ultrasonic generator and is immersed in pre-existing tanks. Equipped with suitable mechanical supports (almost always custom-made), a radiant plate can be positioned on the bottom, on the side walls, or suspended inside the tank.

Washing systems using radiant plates are flexible and scalable, especially when used in medium- and large-scale industrial plants: submersible radiant modules can be installed in existing tanks of various materials and sizes, are easy to replace or repair (as independent units), and are ideal for retrofitting projects when updating or expanding existing systems.

A system with radiant plates allows for optimized distribution of ultrasound radiation thanks to the flexibility and simplicity of positioning, chosen based on the type and quantity of parts being treated. Furthermore, multiple radiant plates can be used (a system that can also be expanded at a later date) to create a modular system that increases power, optimizes spatial coverage, and ensures treatment uniformity.

Advantages of the FASAR UsKIT system:

Flexibility: The ultrasonic power can be adjusted to the size of the load and the type of material being treated. Multiple configurations can be implemented based on the type of product and dirt to be removed. Existing tanks of any material can be used.

Reliability and simplified maintenance: If a module fails, it can be easily isolated and replaced without compromising the operation of the entire system.

Scalability: You start with a basic configuration that can be easily expanded or modified as production needs grow.

Efficiency, energy savings, and customizable functions are achieved through the digital and programmable control of each module.

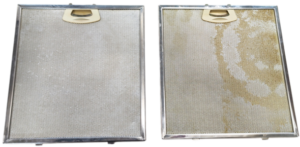

Once you’ve chosen the right container for the type of filter to be treated, position the radiant plates and start the cleaning process: in just a few minutes of washing and the filter is ready for use!

Below is an example of a modular system.

The simplest ultrasonic cleaning system with submersible radiant plates essentially consists of two distinct modules: the rectangular radiant plate (which includes an array of piezoelectric transducers) and an external ultrasonic generator that powers the radiant plate. Complex cleaning systems comprising multiple plates, each powered by its own ultrasonic generator, can easily be implemented, enhancing process flexibility, scalability, and reliability. This makes it easy to convert existing traditional cleaning systems (or parts thereof) into an efficient ultrasonic cleaning machine. The operating frequency of the radiant plate and the ultrasonic generator can be defined based on the application.

Each ultrasonic generator module is electrically connected to the mains supply voltage and to the corresponding radiant plate. When using multiple ultrasonic generators in a three-phase mains-powered system, load balancing must be performed in accordance with standard system criteria. All ultrasonic generator modules belonging to a system (single washing tank) will be connected to a control panel that manages the overall operation of the system. The final system will use a number of modules proportional to the total radiant power required, which in turn is proportional to the capacity of the tank.

Each ultrasonic treatment cell will be managed by a control unit comprising an electronic process board equipped with a display, operator panel, and a series of communication interfaces (RS485 serial port, Ethernet, WiFi, etc.) as needed. This control unit will be equipped with two data communication channels: the first is an internal bus connecting all the generators belonging to the same washing tank, and the second is a communication channel that allows connection to an external host device (such as a PLC or industrial PC) that manages the entire production line.

The best frequencies for industrial ultrasonic cleaning range from 19-25 kHz for treating very dirty, resistant mechanical objects (low frequencies generate intense cavitation, perfect for aggressive cleaning), up to 35-45 kHz for more delicate objects (optical items, jewelry, surgical instruments, etc.) that require thorough cleaning but with a more gentle cavitation effect. Obviously, there is no clear-cut, definitive boundary between these values: it is always advisable to experiment, case by case, to optimize the system parameters. Undoubtedly, the ability to continuously and accurately adjust the output power of our generators (from 20% to 100% of the maximum value), combined with programmable operating frequency, offers the best compromise in terms of versatility and safety in processing most materials.

It is always possible to implement a modular washing system where part of the US generators operates at low frequency to perform a “robust” initial treatment, aimed at removing stubborn dirt, while the other part operates at higher frequencies during the more delicate final phase of the process. It is also possible to program the system to operate simultaneously, according to pre-set cycles, at two different frequencies, possibly with different power levels.

When using a modular system built with independent programmable generators, numerous treatment customization options are available, managed from the control panel, sequencing the various operations with widely programmable power levels and cycle times to meet any requirement. Numerous features can be implemented, determined by the needs of the production process, management complexity, and, ultimately, cost. The great advantage of a modular system is the ability to develop and implement the various functions gradually, as testing progresses and market demands evolve.

T-25 Tank: Ultrasonic cleaning for metal filters

The tanks can be made of any material and are already available, chosen based on the size and quantity of filters to be treated.

The T-25 tank, combined with our range of detergents, is the perfect tool that optimizes the cleaning process of the metal filters used in the professional catering sector, removing any residue of dirt and grease:

- High efficiency

- Reduced treatment times

- Minimum electricity consumption

- Environmental sustainability

An optimal combination of the energetic cavitation action of ultrasound, detergent and temperature offer results otherwise impossible to achieve with traditional washing systems.

An adequately powerful ultrasonic cavitation that propagates inside a fluid is the only way to satisfy the most demanding requests for washing and cleaning metal filters, objects with a complex shape, impossible to clean with traditional means.

The ultrasonic power is generated by a group of piezoelectric transducers that, powered by electrical energy with appropriate power and frequency, convert it into vibrational mechanical energy. This generates millions of microscopic bubbles under vacuum that implode due to the pressure variations generated by the ultrasound, removing the most stubborn dirt and grease particles.

T-25 tank: Technical features

- Machine made in stainless steel, robust and easy to clean.

- Capacity: 25-28 liters.

- External dimensions: (720 x 430 x 330h) mm.

- Internal dimensions of the tank: (450 x 350 x 200h) mm.

- Weight (without liquid): approximately 25 Kg.

- Single-phase power supply: 230 Vac – 50/60 Hz.

- Electric power of the US generator: 700 WRMS (nom. value).

- Electric power of the liquid heating system: 900 WRMS (nom. value).

- Central frequency of the US generator (programmable): 23.5 kHz – 25.5 kHz.

- Continuous variation of the US power supplied with potentiometer.

- Treatment time programming from 1 to 60 minutes.

- Real-time measurement of the temperature of the washing liquid.

- Washing liquid heating (programmable from 20°C to 80°C).

- Automatic modulation of the operating frequency (SWEEP) for optimal distribution of the ultrasonic field inside the tank.

- No. 7 high-performance piezoelectric transducers: maximum US power density inside the tank.

- Backlit LCD display for viewing the status and operating parameters, keyboard for commands and parameter programming.

- High-performance electronic generator suitable for intensive use.

- Automatic forced ventilation system for the US generator.

- Liquid drain tap.

- Stainless steel object holder basket.

- Supply of specific detergent for cleaning metal filters in professional kitchens.

Upon request, the T-25 washing systems can be controlled remotely via serial commands (via Ethernet interface) in accordance with Industry 4.0 requirements.

Our laboratories are available for tests on the parts you are interested in: contact us to organize a demonstration!

For further details, you can contact us and/or consult the brochure:

We specialize in the production of ultrasonic washing and cleaning systems for all types of metal filters in the professional catering sector.

Power and efficiency in ultrasonic treatment with high-performance piezoelectric transducers.

A sophisticated electronic control system manages the operation of the machine: precision, reliability and robustness.